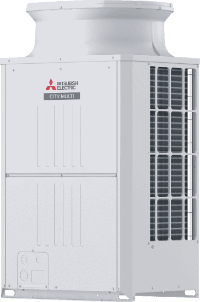

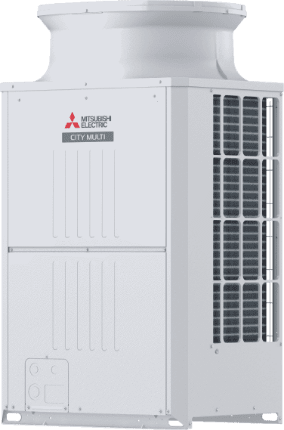

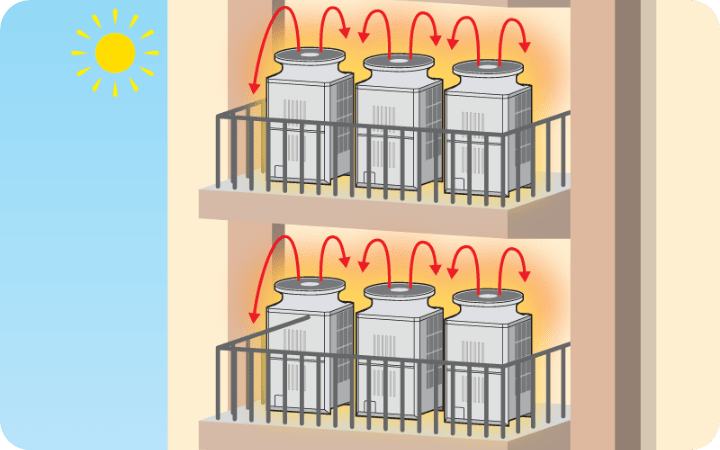

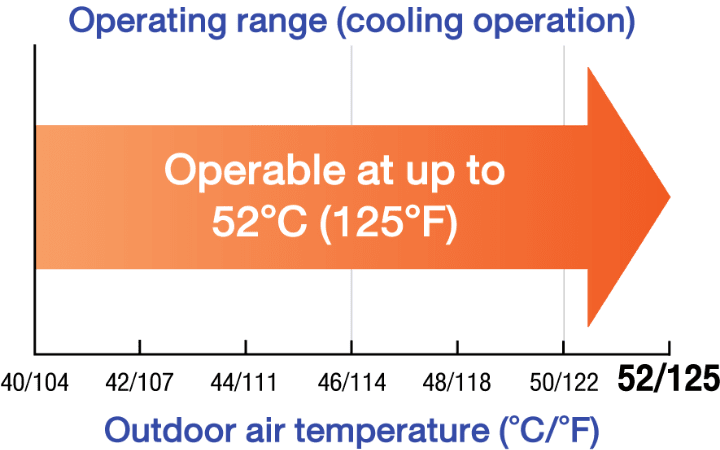

Temperature Operation Outside

For the stability of the system’s operation, long distance pipes can be distributed throughout the building. The condensing unit remains cool even when the outside temperature is as high as 52°C or as low as 10°C.

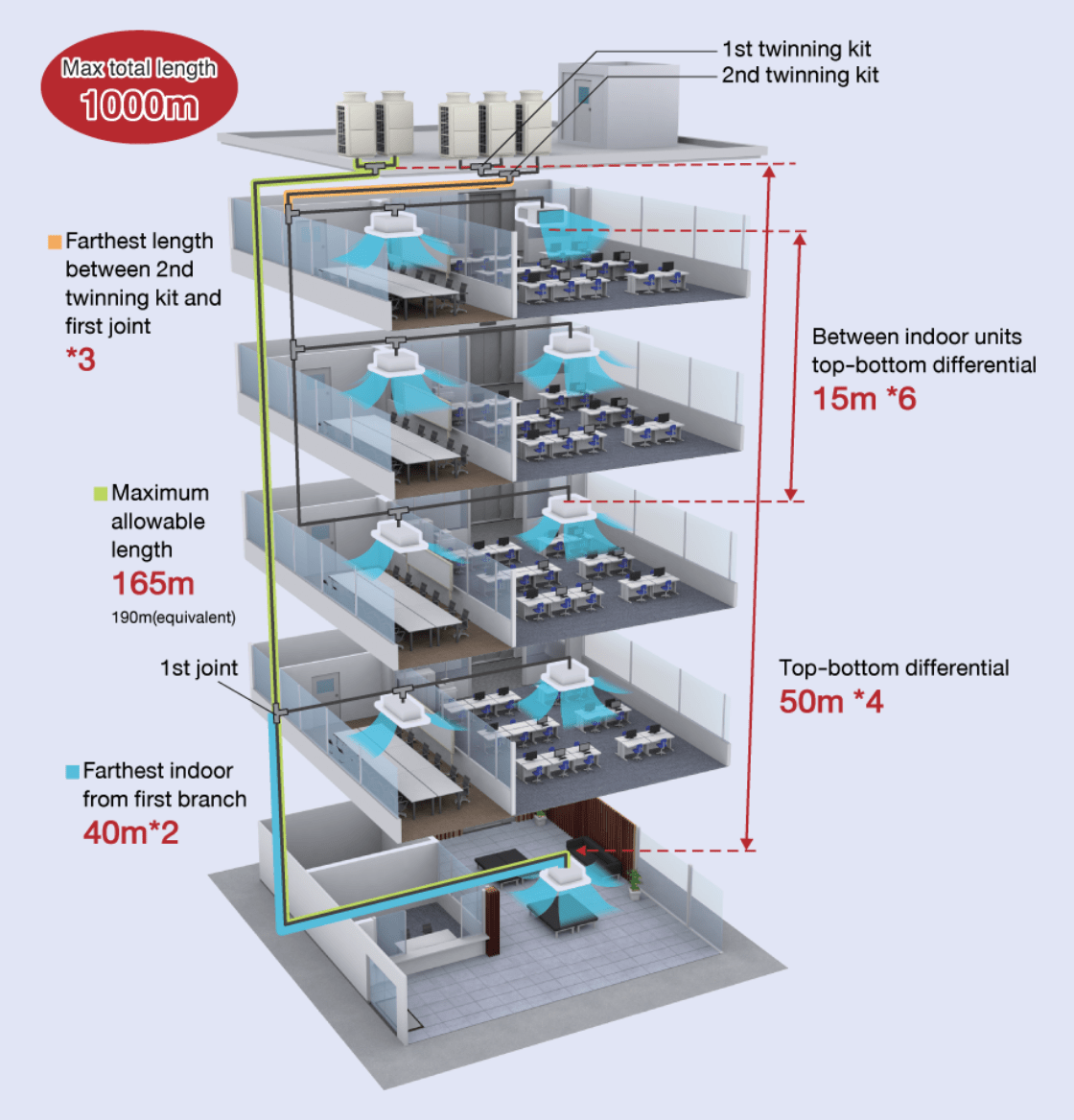

Piping Length

Long-distance pipes can be distributed throughout the building. The pipes can be laid as far as 1,000 meters, suitable for large condominium buildings. The condensing unit can connect up to 50 fan coil units or 130% of the cooling power.

- Length of the refrigerant pipe from the condensing unit to the fan coil unit: 165 meters.

- Farthest distance from first joint to fan coil unit: 40 meters (the distance can be up to 90 meters)

-

Vertical height between condensing unit and fan coil unit:

- In case the condensing unit is higher: 50 meters.

- In case the condensing unit is lower: 40 meters.

Vertical distance between fan coil units: 15 meters.

Compressor - Snap in Core

With Mitsubishi Electric’s unique technology, the efficiency of the compressor is enhanced. The core of the compressor’s motor is designed to fit together like a jigsaw puzzle and the motor is tightly wound with coils instead of welded, resulting in a small but highly efficient compressor.

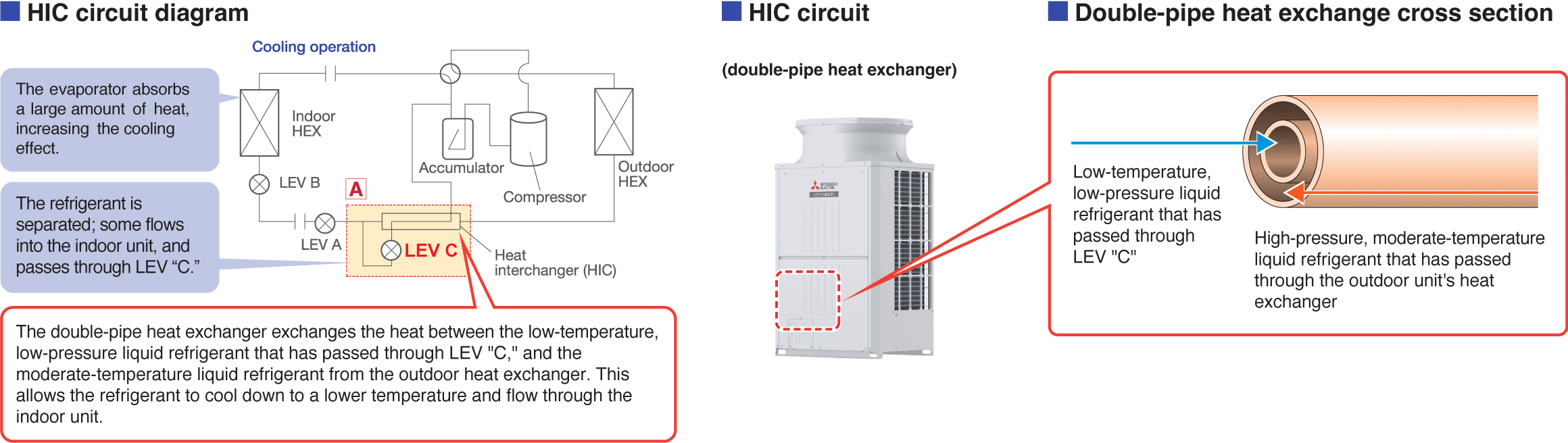

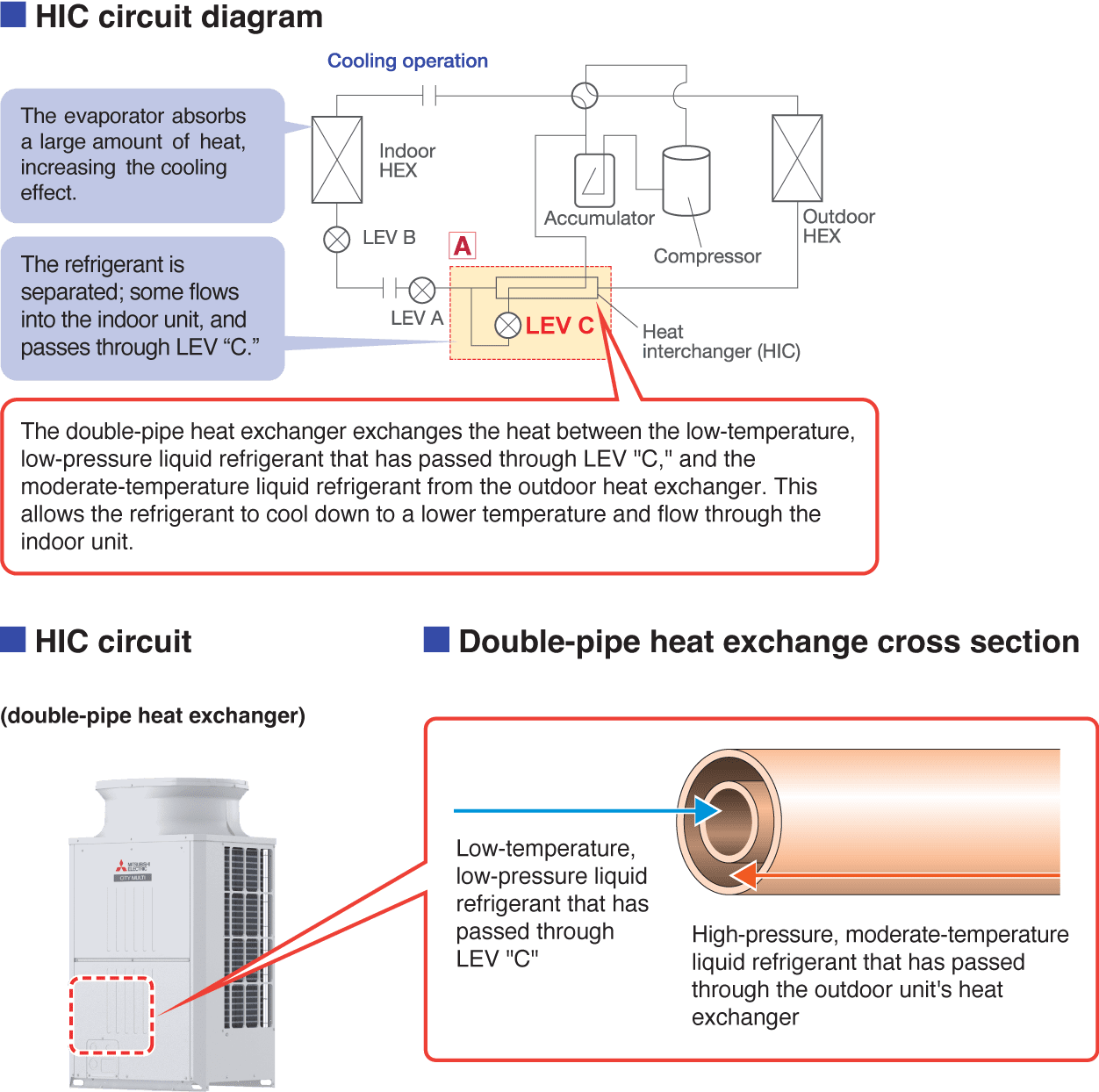

Heat Inter Change (HIC) Circuit

“Double Pipe Heat Exchanger reduces the temperature of the refrigerant” increasing efficiency and saving more energy in heat absorbing.

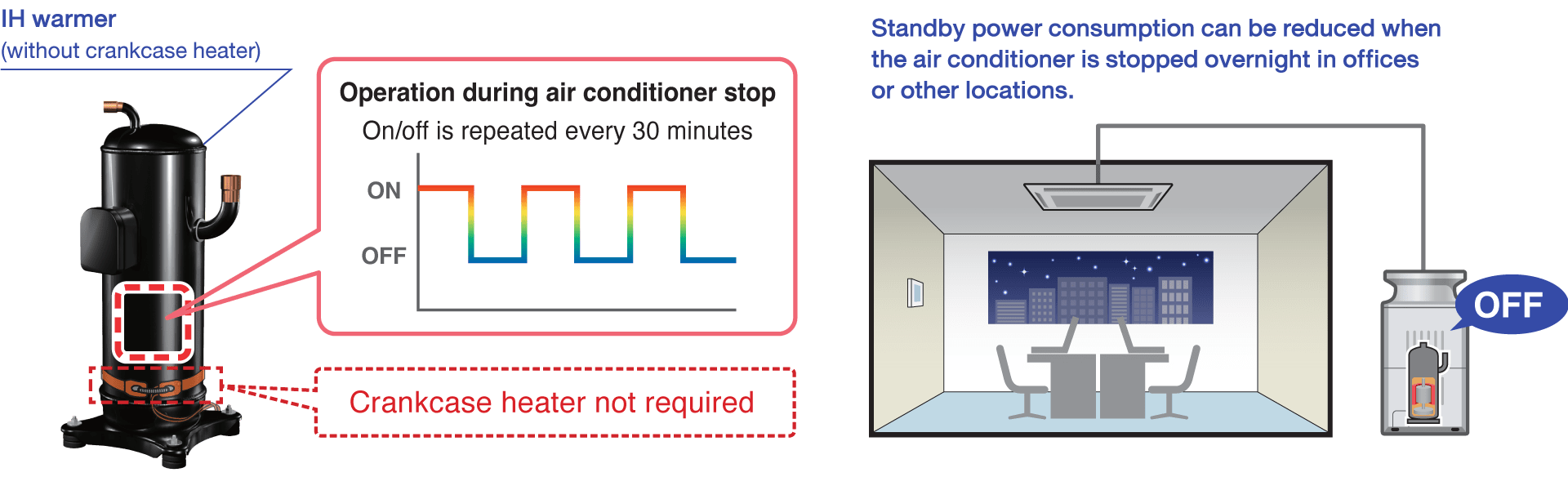

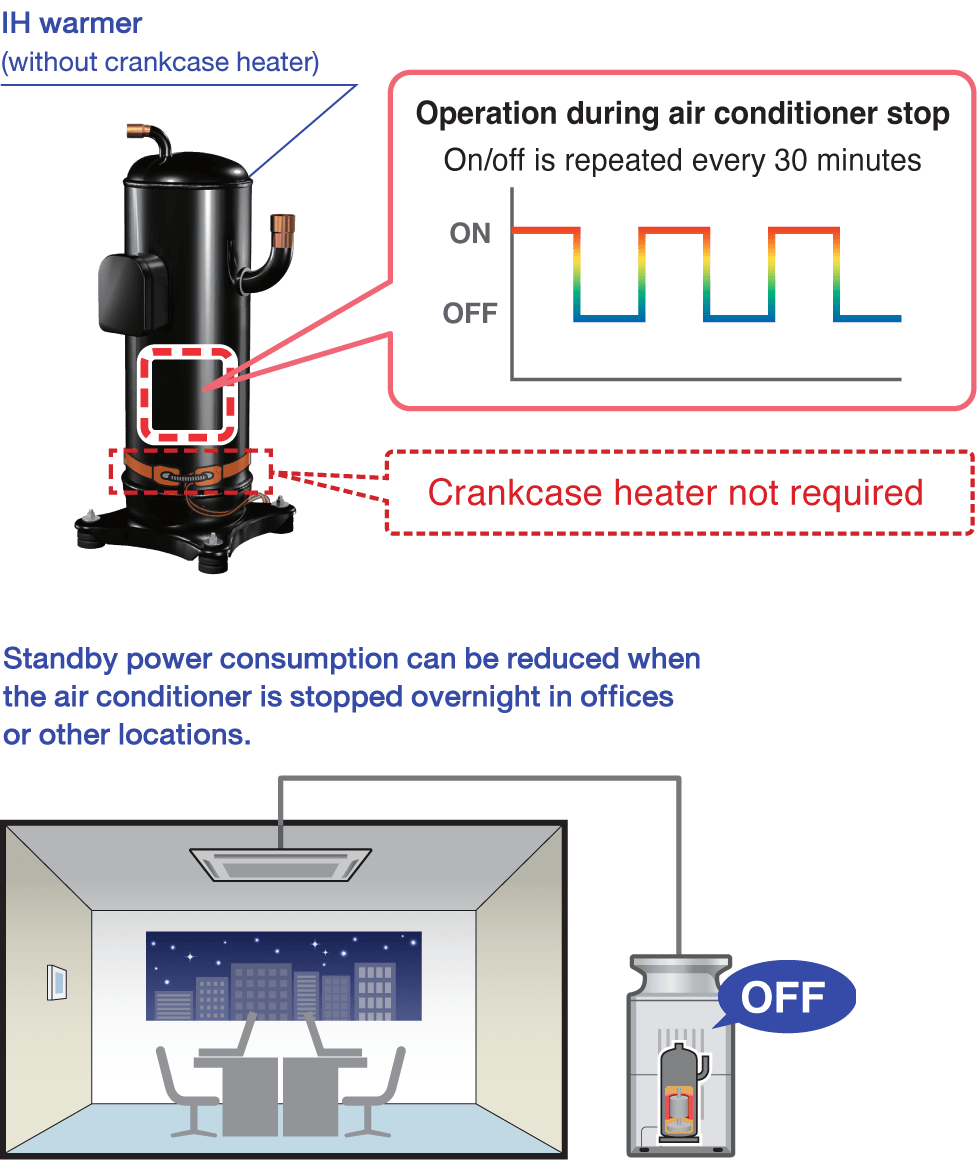

Induction Heating Warmer

Induction heating technology reduces energy consumption. The device uses induction heating to warm up the compressor oil every 30 minutes, making it more energy efficient than using a crankcase heater.

Compressor - Multi-port Mechanism

3 ports to save energy during part load. Multi-port compressors reduce excess energy consumption during partial load by activating only one sub-port, leading to increased air conditioner efficiency.

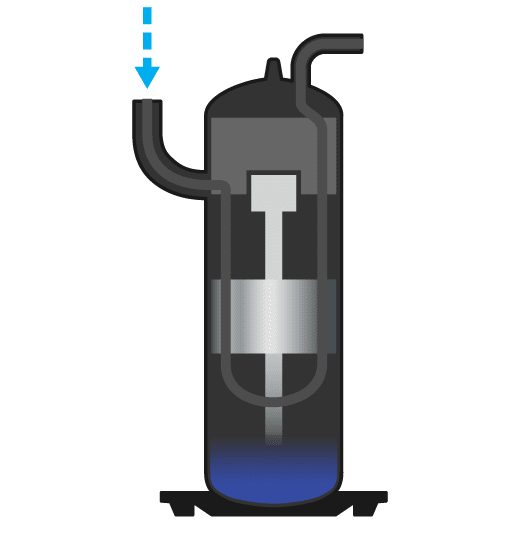

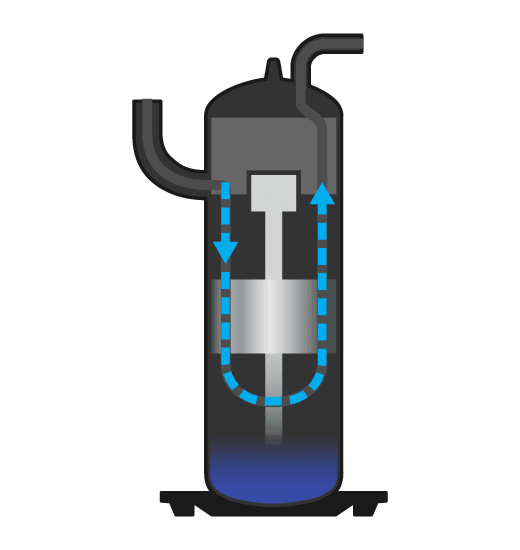

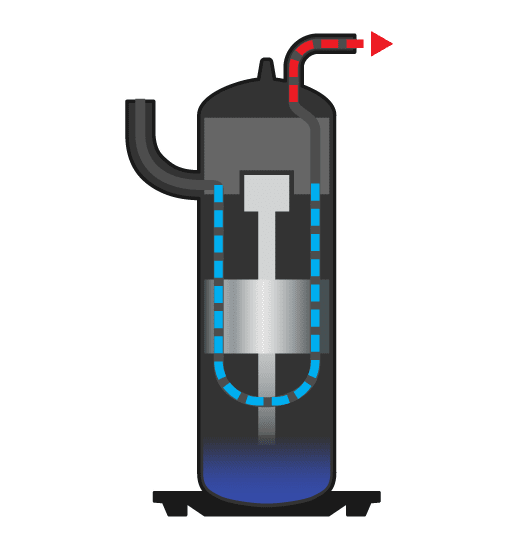

Compressor - Low Pressure Shells

Specially designed to reduce wear and tear and reduce the space required for the high-pressure refrigerant. The low-pressure side refrigerant flows through most of the compressor area and the liquid refrigerant flows down to the bottom of the compressor before high pressure is compressed to prevent damage to the compressor.